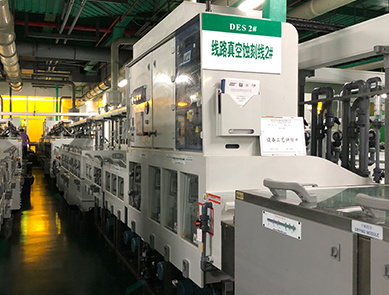

DES (developing and etching film removing line)

Classification:

Inner layer processing

Keyword:

DES (developing and etching film removing line)

Graphic Details

The inner DES line designed by our company; Development + vacuum precision etching + high-pressure film removing line realizes automatic connection, high precision vacuum etching, etching factor reaches 4.5, uniformity reaches 95%, plate thickness 0.05~3.2MM, line width: 2MIL/2MIL. Equipped with Japan imported automatic adding system, monitoring each section of the liquid medicine, to achieve development, etching, de-film automatic pressure adjustment, monitoring. Automation capabilities, and unmanned formation greatly improved. Suitable for HDI, high-density multilayer, packaging substrates, etc.

Key words:

Previous Page

Related Products

Copper Reduction Production Line

Horizontal black hole line (eclipse line)

Online Message